TURBOTHERM®

The economic solution for variothermal temperature control

In corporation with the University Pforzheim and after 4 years of development, we are introducing a new energy- and cost saving system for selective heating of critical areas in injection mold cavities on the market.

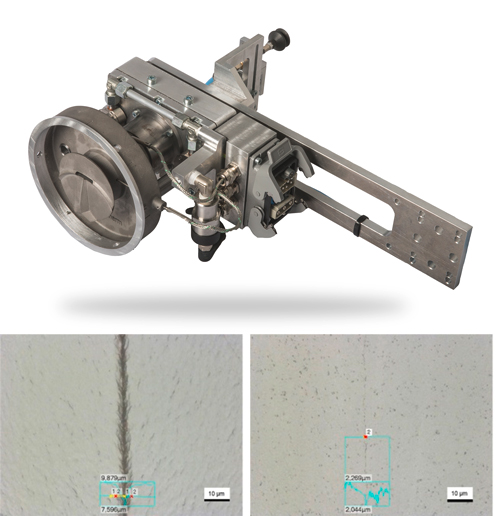

A patented combination of turbulent airflow, highly efficient 3D-printed heating-nozzles, tailored to the molded part, air acceleration based on Venturi-principals and a heat recirculation-sleeve contributes to a highly efficient variothermal process control system for injection molding.

TURBOTHERM® is going to be available as of January 2018