![]()

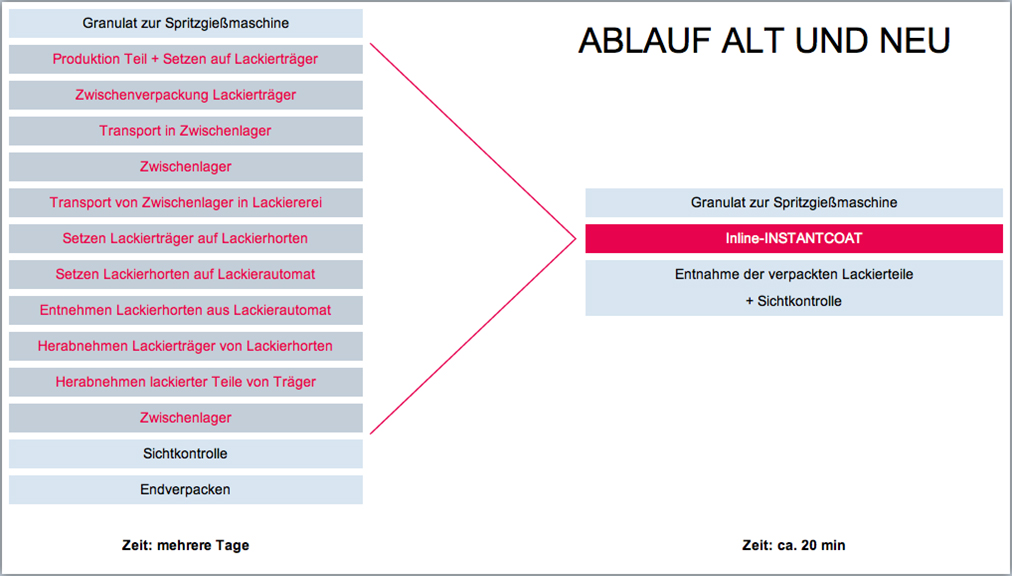

"By direct and fully automated linking of injection moulding, coating and final packaging with INSTANTCOAT® Plus we have reached the presently conceivable optimum in efficiency and product quality."

Dipl.-Ing. Michael Däbritz

Manager of VARIOPLAST®

- Material input

- Production scrap

- Personnel Costs

- Cycle Time

- Response time to problems

- Storage time of parts before coating

Critical aspects are improvement of part quality, process repeatability and flexibility:

- Regular coating layer thickness

- Improved surface appearance

- Improved coating adhesion (dirt-free parts)

- Part defects directly recognizable during process

- Shorter reaction time in case of malfunctions

- Process parameters repeatable and coordinated.

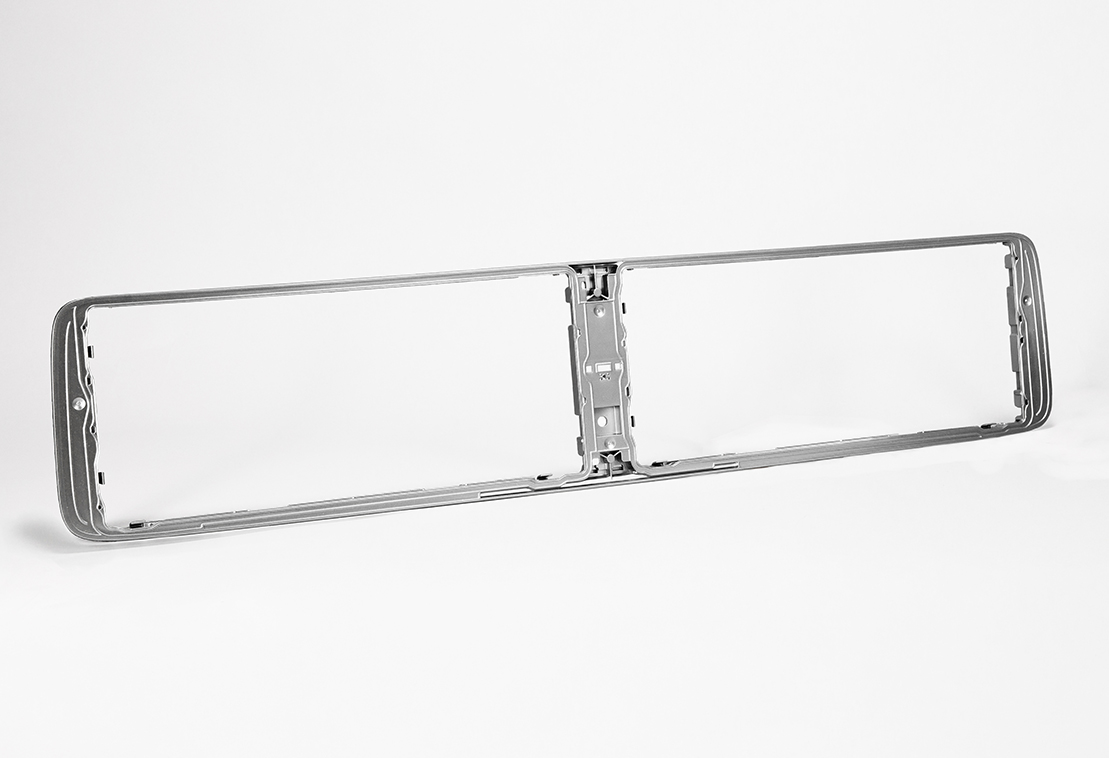

Mountingframe

2K-Injection Moulding + CO2 pre-cleaning + coating + dry + coating + dry

INSTANTCOAT®: 75% reduction of the ecological grey footprint

Source:

![]()

Download

High-tech injection molding

2K-Injection Moulding + Sheet Metal Overmolding + Insert Overmolding + US-Welding + Pad Printing + polishing + Drill

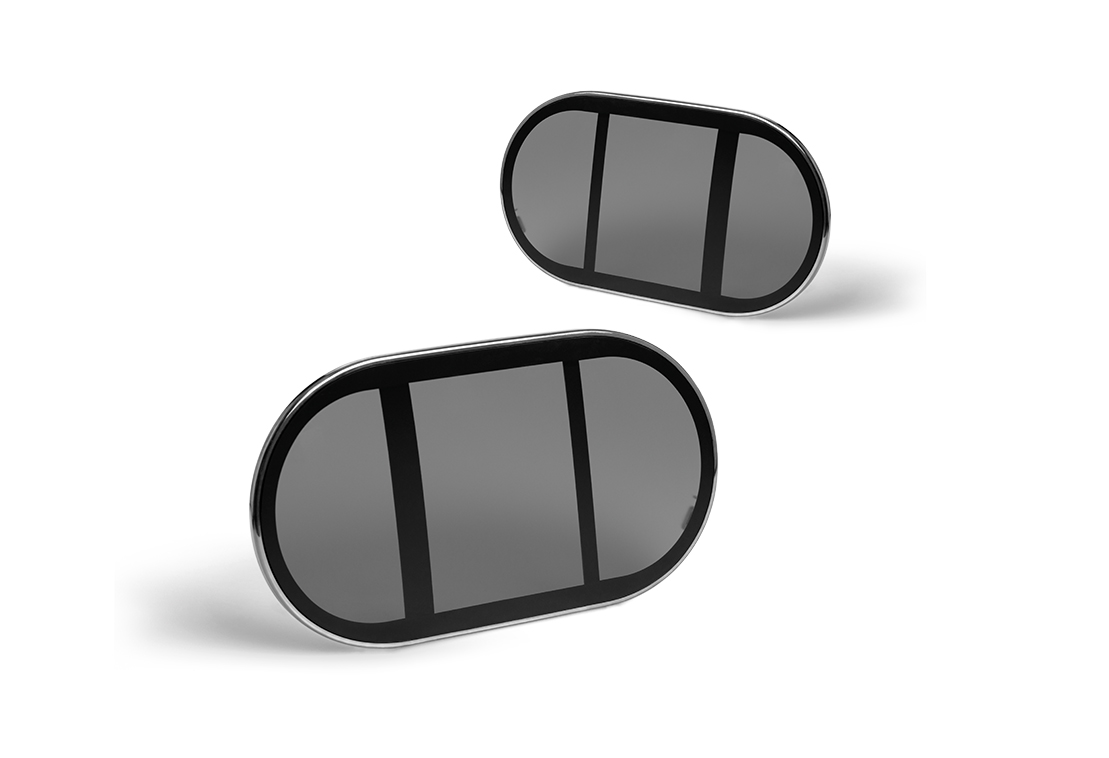

Black Panel Technology

2K-Injection Moulding + Variothermie + Pad Printing + PVD-Coating + coating + US-Welding + Laser cutting